|

How to Design & Build Ultra-Low Cost

Truss Structures

for the absolute

Minimum weight, Steel Usage, and Cost

1Spread out the "load

path" from the supports to the loads bear down.

Whenever

distributed loads have conventrated supports, then the supports must spread out

their support accordingly.

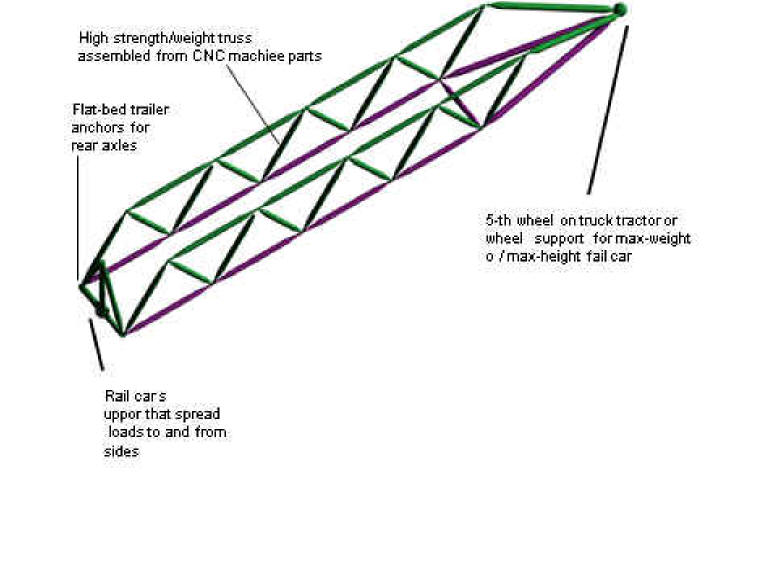

The following

illustration applies to applications for Flat-bed truck traiers (on the

right half) and for rail cars bodies (on the left side) with some

cross-over applications as noted.

Trusses have alwaybeen the highest

strength/weight,

and now can be the lowest cost

The high strength per weight at low cost would be valuable

for:

Chasses for trucks, semi-tractors, farm

equipment, Earth-moving equipment, etc.

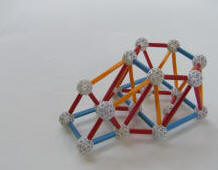

Chasses for racing cars and trucks, which has

been used since Maserati developed the “birdcage” space frame in the early

1960's. which consisted of 200 welded tubes that reinforces in high stress

areas! The techniques of this page need no welding, no reinforcing, and, with

more efficient layout may need up to five times fewer tubes because they follow load paths (as discussed below) so they cost so

much less that these design innovations could evolve into production

models. See Zometool model of a fully-triangulated frame for an

off-road racing truck with narrow engine

compartment on the left beside front wheels (not shown):

Long span structures that support heavy

loads, like railroad cars and locomotive chasses and elevated rail structures

(see first truss shape example below)

Light-weight structures that have to accelerate fast

as may be needed to move challenging masses fast.

Anchoring and concentrated loads in aerospace structures that benefit

from load-path analysis

Low-cost machine frames that can be backward

“drop-in” replacements for nard-to-build weldments: This is the focus on the

Steel Reduction Workshop.

OPTIMIZING DFM FOR

TRUSSES

How to optimize DFM for the highest strength per weight on the

lowest fabrication cost, material cost, and overhead cost:

For most of the opening opportunities listed above and more, the major .

strategies are the following DFM techniques

Automated CNC Fabrication

Design system architecture to be all fabricated on automated CNC machine

tools (milling machines, lates, swagging machines, etc) with pre-fab parts

rigidly and precisely by DFM techniques described below.

The triangles in trusses are these trusses

mostly have somewhat different shapces, which can be easily handled by Cellular

Manufacturing Cells using Mass

Customization principles; see

Cellular/Flexible

Manufacturing

DESIGNING THE OPTIMAL TRUSS

SHAPE

Synthesize the optimal truss shape in the following these examples from

simple planar truss to 3D space frames:

2D Planar

Truss: The Warren

Truss:

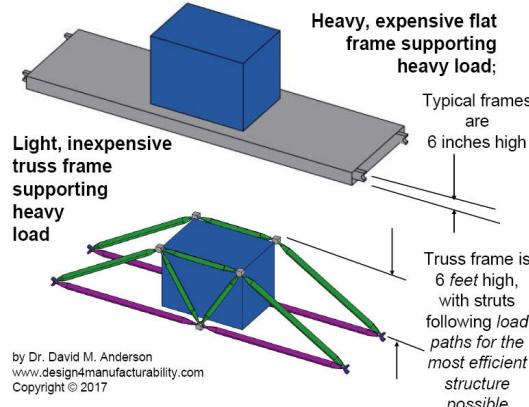

The three equilateral triangle Warren (zig-zag) truss has several times

strength per weight ratio than a flat beam because flat beam stresses

are always much higher near the center, whereas trusses can be designed so

that each strut has the same load and they are much lower, as shown in the

client example at the right.

A simple but higher version of this is the "King Post" truss, that

consists of two right-angle triangle. On the other hand, more

triangles in Warren truss would be lower but less efficient than catenary

trusses, (discussed below) which is the most efficient truss for

spans.

The Catenary Truss

A very efficient truss for supporting uniform loads is the "catenary truss.”

A catenary is the shape formed by a chain hanging between two level

points. Ancient builders would trace this shape and build masonry

domes and arches using this shape because the loads would transfer cleanly

along columns of blocks without needing any sideways stresses, This

catenaries are very efficient. Some of the machinery catenary trusses

presented below also have the catenary in compression and do not need

sideways bracing. Trusses with the catenary in tension can be designed

to have constant stress, thus being made in one piece.

Structurally,

the catenary truss is the ideal beam because the catenary shape matches

the load curve for beams that are supported at the ends, thus providing the

greatest strength for the least material, the lightest weight, and the lowest

cost. This type of truss is utilized in the most advanced bridges

The inverse of this is a suspension bridge in which the catenary

is a long cable with smaller cables connected to the bridge surface.

Catenary trusses, as shown below, can be utilized as cost-efficient frame work

that need to support weights (loads) over challenging distances, especially for

sub-frames that need to be light for accelerations. This may be the best design

approach for long beams like large machinery or frames for the lightest railroad

tracks.

Uniform

loadc atenary

Truss

with

constant-stress

lower"strap"

This truss will support a

uniform load, like on a floor or a road bed, and exert a constant stree on

the lower "strap" that supports the truss at each end.

Therefore, the strap can be the same thickness and be made of one piece of

metal or composite carbon fiber.

See Figure 16.4 from Chapter 16,

"Finding Efficient Forms for Trusses," from Design of Building Trusses,

by James Ambrose, Professor of Architecture, USC. 1994, John

Wiley & Sons.

Catenary

supporting

constant stress

"bridge" member

In

this truss, a true catenary arch member supports the a constant stress

"bridge" surface member, which can be made from a one piece of metal

of composite carbon fiber, which greatly simplifies construction. The

inverse of the catenary could be suspended from two towers, like the Golden

Gate Bridge. Note that no diagonal struts would be needed, which would

also simply machinery construction. See Figure 16.7 from the above

reference, in

Chapter 16, "Finding Efficient Forms for Trusses,"

Like all trusses discussed above, all the parts can be built automatically on

ordinary CNC machine tools. assembled by non-skilled labor, and retain

neat treatments or cold-rolled strength of the raw materials.

3D SPACE FRAMES

Space frames are three dimensional trusses that are fully triangulated and

can resust linear forces in all directions and resist torsion along all axes.

The simplest space frams is the tetrahedron which

can support a point load on three struts (like a camera on a tripod.

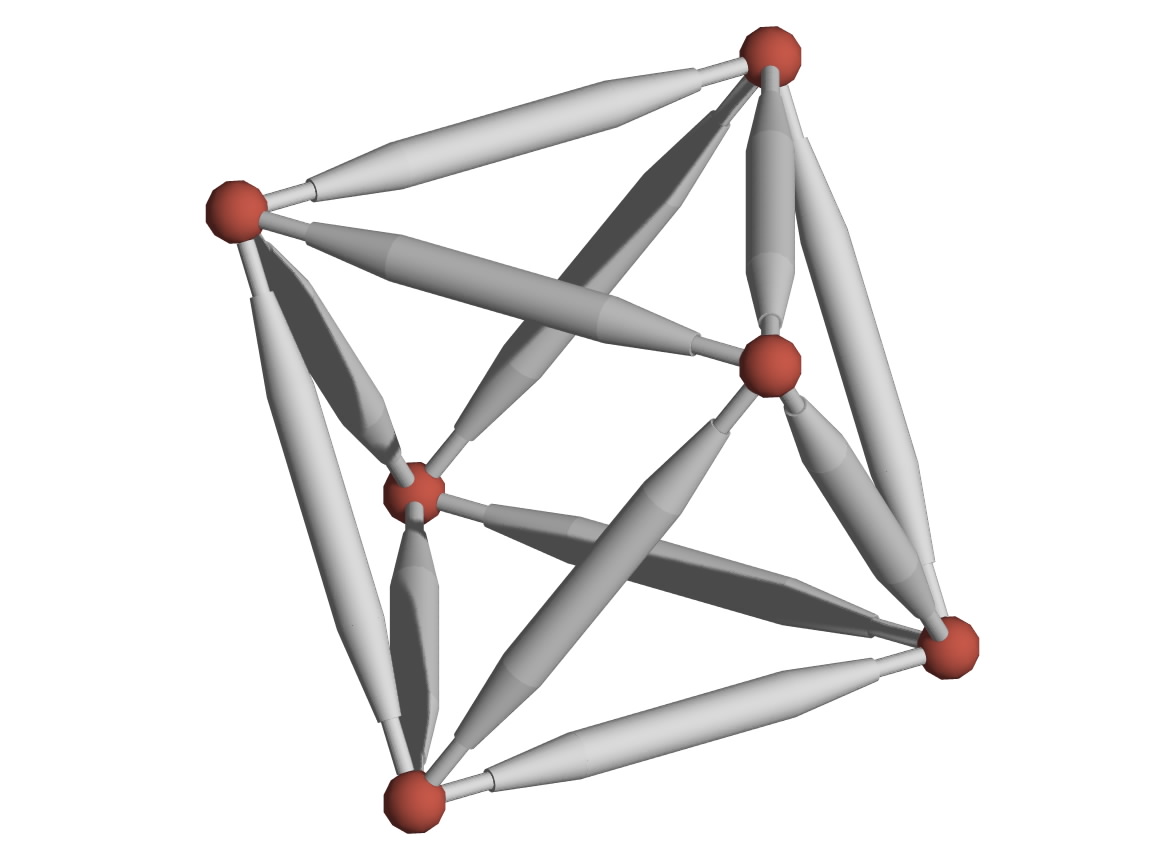

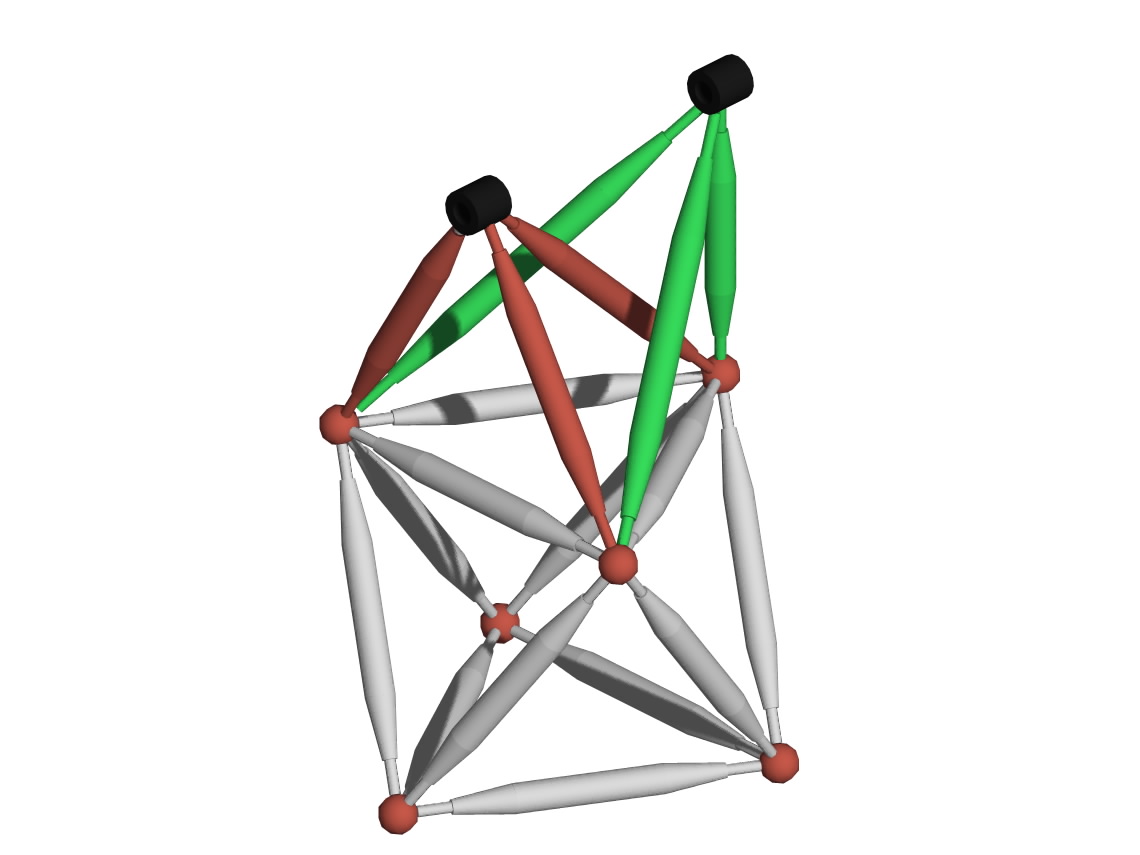

The Octahedron

The Octahedron is a true space frame that

will support a solid object

on the top triangle while it and the truss is

supported on the bottom triangle.

MORE EXAMPLES

AND CONCEPTS

Truss Frame with Bearing Mounts for Shaft.

© 2018 by Dr. David M. Anderson.

2018 by Dr. David M. Anderson.

Two "tripods" can be bolted to any truss (in

this case, the above octahedron) to mount other structures like mount bearing

blocks to rigidly support machine shafts, axles, pivots, or any rotating

members. The bearing blocks have bearing mount surfaces bored and reamed

and also tapped holes on the outer surface on which to bolt the struts.

The tripod mounts result in fully triangulated

rigidity and is much stronger per weight than the usual techniques us using

heavy plates or weldments to mount bearings

If a single structural mount was needed, one tripod could be

utilized with an appropriate mounting surface.

Any subassembly could be bolted to any side

or multiple sides of any basic truss frame for functionality, for instance,

bearing blocks, in any plane.

The Strategy

The

strategy would be to

commercialize

proven parts with backwards compatible replacements with the same

functionality and strength (possibly enhanced) with much less total cost and

weight. This

would provide cost reduction now on existing products. This would also encourage

a leap-frog strategy where these low-cost parts could then become the

basis for new generation products.

The specific strategy to eliminate the abovementioned costs would be to

create an optimized concept/architecture for constant-stress trusses and

structures (which, by definition, use the least material) with the following

steps.

This strategy and approache are described

and justifies in theCost and steel

reduction workshop on its own page.n page.

The Approach

The approach would be based on the following premises:

Fabrication. All machined parts would be small enough to be set up

and made quickly on readily-available CNC machine tools in a single setup

(Guideline P14 in the

DFM book, which specifies that all operations should be

done in one setup on versatile CNC machine tools).

Welded

parts would be limited to those that are small enough to be machined after welding by the typical in-house machine tools. This

may be appropriate for bearing blocks and other junction parts if not feasible

to machine from a single block.

Assembly. Precise alignment of

these assembled pieces would be assured by the programmable part manufacture.

Mass Customized Tooling. Dr. Anderson has

written two books

on mass customization, and had experience designing flexible tooling as

Manager of Flexible Manufacturing at Intel's Systems Group and his own

Anderson Automation, Inc. Based on all this, his workshops show how to

design flexible processes that can programmably offer variety with less cost,

time, space, weight, and material usage.

The general principles of mass

customizing process design are summarized on the web article shows flexible processes for electronics

(Figure 1) and flexible processes for fabricated products (Figure 2) at

http://www.build-to-order-consulting.com/mc.htm . Another big

benefit of flexible tooling is that it enables spec changes or

customer-induced changes to be implemented faster than with inflexible

designs built in hard tooling, thus keeping them off the critical

path.

Steps for Reducing

Cost on Large Parts and Assemblies:

• Identify existing loads,

directions, and attachment points, which would then be graphically represented.

In a workshop setting, these could be projected from a active CAD screen or printed on several sheets of large paper

with dark lines for the next step.

• Brainstorm on various ways to

support these loads, with many ideas sketched on many printouts.

• Then

optimize the design of these parts for manufacturability and currently

engineered manufacturing strategies for trusses, assembling plates and bar

stock, and "space frames."

Trusses consist of struts

and nodes:

Struts. Purely tension members could be made of rods; compression struts

must be axisymmetric with the load path and wide enough to resist

buckling. This favors

tubing with threaded holes at the end to bolt to the node blocks. Very thick-wall

tubing could be plugged with threaded disks that could be joined to the tubing

with an automatically welded low-heat axisymmetric weld. For smaller thick-wall thickness, a clean,

inexpensive strut could be made by swagging down the ends to just past the tap

diameter for tapping threads that could then be bolted to the node blocks.

Swagged ubes are shown in the illustrations above (in grey), which can be inexpensively

procured from a swagging shop. In one application, a swaged tube cost

$40 for a 25 inch long tube, 2.5" OD, with an

1/8" wall that that included drilling-and-taping and facing off for a

precision length (wall thickness can go up to 1/4" and higher). The swagged struts can be made quite large

and strong, as was pursued in workshops for Caterpillar's underground coal

mining front loaders Finmechanica's

four-axle trailers and other workshops indicated by the blue hyperlinks

on the client page. In workshop exercises, Dr. Anderson leads a

company team to brainstorm on many concepts for struts-and-nodes to support all

the hardware in a frame or structure.

The nodes would have bolt holes for

the struts and all hardware that bolts to the structure.

Node

Blocks. Each node block would be designed and dimensioned so that

all operations for node attachment and and object mounting holes would be made in one setup (Guideline P14)

on an ordinary CNC machine tool. Families of similar parts could be

machined on

flexible fixtures that would be able to make all parts in the family

without setup delays and extra cost. The illustrations below show spherical

nodes (in red) for clarity. Actual nodes would each be milled out of bar

stock using various DFM design techniques to attach the struts and all the

hardware that needs to be supported. Dr.

Anderson helps companies design these through consulting after the

workshop and through remote consulting and design studies.

Workshops. Many

customized workshops have been conducted by Dr.

Anderson

This one-day workshop will apply unique DFM principle to

large parts for half the cost or better and significantly less steel

consumption.

This is the most effective way to reduce cost on existing products

because it focuses the most effective half-cost DFM principles on the least

manufacturable module in industrial machinery: structures and frames, which

usually are hogged out of large blocks or are welded and then go to

straightening, grinding, and drilling on mega-machines (see cost savings

summarized below).

The workshop will show a small group of your people how to quickly design

backward-compatible replacements that can “drop in” to existing product designs

for significant near-term cost savings without needing a full product

development cycle.

Workshop Format

The group would explore some of the most promising

opportunities in the workshop to the point where they look feasible and it is

clear how to proceed at which point responsibility could be assigned to pursue

each opportunity.

The group would also identify future opportunities to

be explored later based on pre-workshop research that will have identified some

opportunities. Opportunities will be summarized and then the workshop group will

vote on them for a baseline prioritization of opportunities.

Pre-workshop company research

should also plot steel cost from the time current

products were designed and extrapolate price trends into the future.

Audience. Product development team with all designated and potential

members, with at least one person representing each function and one person

knowledgeable about each proposed candidate structure. The workshop would

benefit from close proximity to the physical structures being analyzed.

Prerequisite: When a DFM class is give, workshop

attendees should attend the two-day DFM seminar first.

For a stand-alone workshop, the prerequisite would be be familiarity with the

original part, its brackets, and everything that attaches to them, CAD skills,

and familiarity with the parts welding process, and company or vendor machine

shop operations.

This workshop can be offered without the full DFM class if a

small team attends an upcoming webinar:

April

& Sept. webinars on Design for Lean

Manufacturing

2-day webinar:

April 19-22 and Sept 20-23 from 1-5 PM EST

Complete description at: https://qualitysupportgroup.com/design-for-lean-manufacturing/

Team

members can get a 15% discount is available (on request) 2 or more people from

the same company

Alternative: Consulting with company CAD

engineer.

An alternative would be ask Dr.

Anderson to do the above as a

design study

on a consulting basis, working with relevant company engineers and/or CAD

engineers. The

joint effort would present the most promising approaches for the company to

evaluate, select, and implement. Dr. Anderson is particularly effective for

complex parts that could benefit from more manufacturable design concepts and

concurrently engineered low-cost tooling and processing. He is in a unique

position to do machining/welding tradeoffs, since he once had his own machine

shop and has done welding since his college years.

He also has to-scale

CAD models for other layouts, like front and rear wheel loader frames, on

which he will work exclusive with the first mover to

contact him. Because of his

ethics code (from the Institute of Management Consultants) he will avoid

conflicts-of-interest by not working with direct competitors, so that means

first-come-first-serve for enlisting his considerable experience on these

techniques that he originated. See client engagements that included this

Steel/Cost Reduction workshop, as indicated by blue hyperlinks on his

clients page. For clients with new challenges,

he has a vast library of generic struts already drawn.

All of these

principles on DFM can be included in

your customized

class and workshop on DFM

or

the Most Effective

Product Development class

Here is an email you can use to send this

information around:

To: all

I just found a heavily-illustrated web page that shows

how to:

a) Design

very high strength/weight structures

that avoid the high cost, material use, and skill demands of

weldments and replace all that with automatically CNC- machined

parts that can be quickly assembled rigidly and precisely by the DFM

techniques described by the 50 articles on this site.

`b)

Provide immediate cost and steel reduction

on existing products with backward-compatible "drop-in"

replacement structures which next-generation products

can be based on. `b)

Provide immediate cost and steel reduction

on existing products with backward-compatible "drop-in"

replacement structures which next-generation products

can be based on.

See www.design4manufacturability.com/low-cost-trusses.htm

new Article:

The Most Advanced Product Development Course

by the author of all 50 DFM

article in this site.

New Article: Strategy

If you want to discuss Trusses by phone ot

e-mail, fill out this form:

If your company makes any products

that have similar opportunities, contact Dr. Anderson for your own proposal for

workshops or design studies that will show you how greatly lower the cost of

your hardest-to-design parts. As a Certified Management Consultant (CMC),

Dr. Anderson's high ethical standards

prevent him from doing this for direct competitors, which means the first

to bring him in gets a unique competitive advantage.

To discuss this further, contact:

Dr. David M. Anderson, P.E.; CMC; Fellow, ASME

HalfCostProducts.com

www.design4manufacturability.com

www.build-to-order-consulting.com

1-805-924-0100;

anderson@build-to-order-consulting.com

[DFM Consulting] [DFM

Seminars]

[DFM Books] [Credentials]

[Clients] [Site Map]

[DFM article]

[Half Cost Products site] [Standardization

article] [Mass Customization article]

[BTO article] [Rationalization

article]

Copyright © 2022 by David M. Anderso1

|